Concrete Pipe Making Machine

To make cement pipe with an inner diameter of 400-3000mm and a length of 1000-5000mm , the raw materials are compacted in high speed roller rotation and the concrete in the mould will be formed a c

To make cement pipe with an inner diameter of 400-3000mm and a length of 1000-5000mm , the raw materials are compacted in high speed roller rotation and the concrete in the mould will be formed a c

To make cement pipe with an inner diameter of 400-3000mm and a length of 1000-5000mm , the raw materials are compacted in high speed roller rotation and the concrete in the mould will be formed a cement pipe with the centrifugal force. When the formed cement pipe reaches standard strength through steam and natural curing, the average efficiency is 6-8 each hour. The machine is easy to operate, runs smoothly, is reliable and durable, and has a low failure rate.

Centrifugal socket type self-stressed reinforced concrete water transmission pipe mould is mainly composed of two semi-circle cylinders, inner mould, outer mould, insert port mould, running wheel and other parts, which has enough strength and rigidity.

The mould has reasonable design (safe, reliable and easy to disassemble and assemble) in an advanced manufacturing technology, that is an ideal choice for you.

Features:

1, One operator required, reducing labor costs;

2,Low power consumption, money saving;

3, The patented seamless stack is easy for lifting;

4,The efficiency is greatly raised and the intensity of labor is decreased;

5, Easy to operate;

6; The block stacks are consistent, no missing corners and no breakage.

Production line Equipment

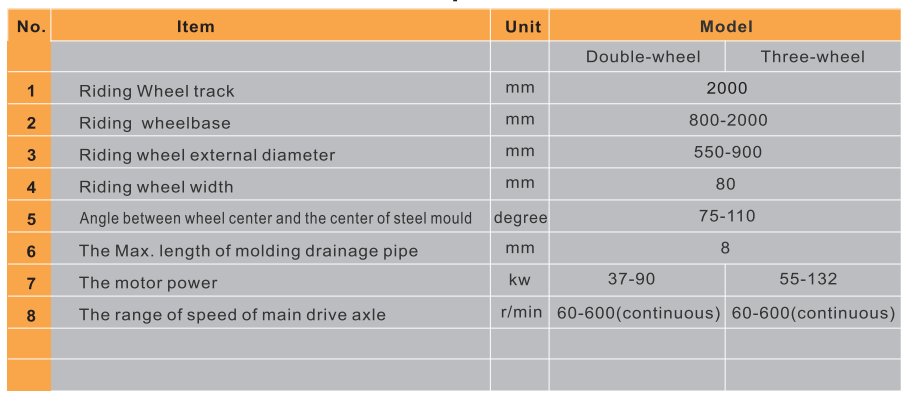

1、 Suspension Roller Type Cement Pipe Machine

2、 Automatic Feeding machine

3、 Automatic Cage Forming Welder

4、Portal Crane

5、De-Moulding Agent

6、Special Screw for Mould